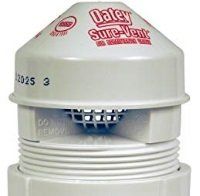

What are some Common problems with an Air Admittance Valve?

Although air admittance valves are checked for their durability against rodents, sometimes they cannot carry on. Holes can sometimes still be chewed through if rodents are a persistent issue. Chromed or galvanized steel tubes installation may be more difficult and even can lead to improper installations causing the AAV's to fail.

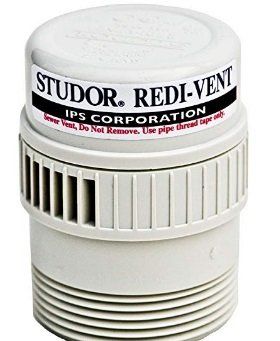

Proper thread sealant is important to properly seal the threads between the valve and adjoining pipe connection so that the sewer gas odors don't leak out. Space under the sink can be tight and the AAV's at the back so accessibility can be difficult. The AAV's sometimes are not properly installed and are located behind a wall making it impossible to access without cutting open walls.

The bottom edge of the AAV's inlet opening must be at least 4 inches above the drainage trap and not all applications have this space available. The AAV is stuck and won't unscrew because the space above it doesn't exist for the threads to come all the way out and then the pipe extension may need to be cut and the adapter connection lowered to allow for the replacement or installation of the AAV.

It can happen, the air admittance valve is not working like it should, then maybe a replacement is needed.

Sometimes you may find that even with AAVs, there are still sewer odors and clogs. While this is rare, it is possible. Bear in mind that these valves should last many years, so if they are just lasting a year or so there may be some other issues that need addressing.